About Tunneling Project

When complete, one of North America’s largest infrastructure projects will cover 19 kilometres, with 25 stations, intersect with 5 other transit methods, and will save travellers 60% of their time in crossing the city. The line will combine 10km of tunnels, with surface and “cut-and-cover” construction.

Project Summary

After NLT’s several successful installs, the construction group handling the project began to investigate an integrated NLT-based underground network that would serve many functions within the construction of the tunnel.

The first goal was to provide communications solution to the three “mining” stations of project. The system was required to provide complete uninterrupted communications between surface staff and teams that were working underground. Further technologies could be integrated later in the project.

This included monitoring of activities at the face with sensors, video/CCTV, and retrieving real-time data from construction equipment. The first phase of the project was to implement a Wi-Fi based communications system. The motivation was to be able to monitor 24/7 when work activities were not taking place (such as at night or on weekends). Each of the three sites required a custom system, each supported by its own team, but the oversight was managed centrally, so they required a system with similar designs across each site.

Overview and Requirements

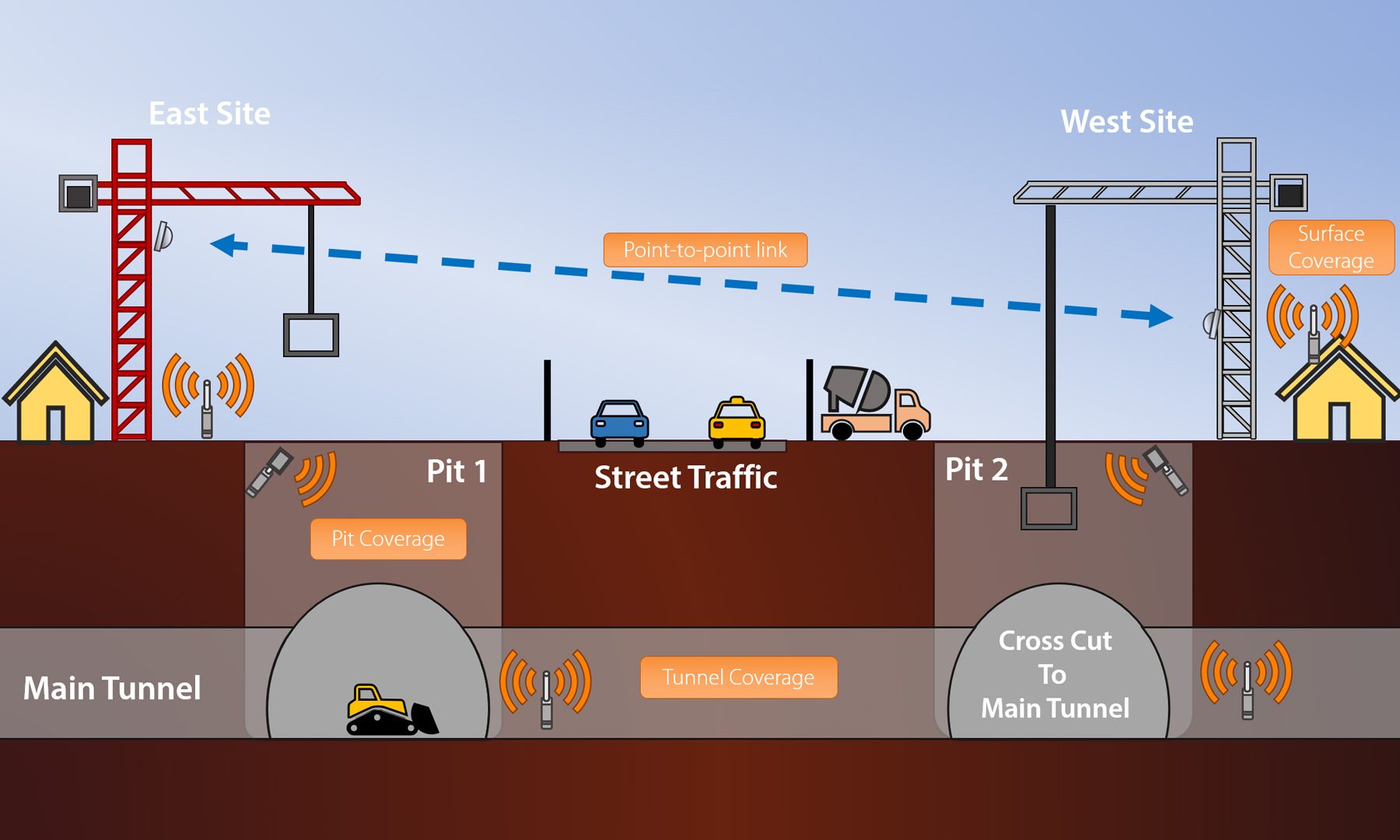

Each site had one or two excavation portals to the underground work areas. After the portals (or work pits) were created, they would create cross-cuts digging north, and then connect the portals to the main tunnel, which grew to the east and to the west of each cross-cut. The communication system, the network, and the Wi-Fi access is required to grow as the tunnel grows.

Each of the three sites had its own design constraints, but the common requirements across all three sites included:

- Combined surface and underground communication.

- Integration with existing VHF based radio system for crane operations.

- Providing coverage to the large pits (portals).

- Outdoor electronics, that can be exposed to weather and the temperature swings (35 C summers -20 C winters)

NLT solution summary

Each of the three sites required customized systems that included the following:

- Local servers

- N-Connex Edge

- N-Connex Bolts

- NLT’s Wi-Fi communications Solution

- Wireless Link between portals at the surface

- Pre-terminated IP67 Cat6 ethernet cable

- Commissioning and support services

Challenges

Point-to point link at the Surface – Two of the three sites had dual excavations that were separated by busy main streets, and as a result, could not be networked with physical cabling. NLT’s solution was to use a point-to-point radio link, with each radio mounted on a crane. The solution provided a robust connection with enough bandwidth for the full communication system, that was able to handle harsh weather.

Wi-Fi Congestion – Given that each site was located at busy urban intersections, with dense residential buildings and businesses within proximity, the Wi-Fi availability of the are has challenges on the surface. While NLT continued to use 2.4GHz underground, the solution at the surface included the use of 5GHz channels, and in some cases, directional antennas to ensure appropriate signal availability.

Integration with UHF System – The crane operators and riggers had a dedicated UHF system that would not be removed, and needed to be integrated with the new communications system. The NLT Wi-Fi based radio solution offers a gateway that allows integration between the two technologies, turning the UHF system into a virtual channel within the managed Wi-Fi radio system. This integration allowed the crane operators to have the ability to communicate with staff who were underground or in the offices.